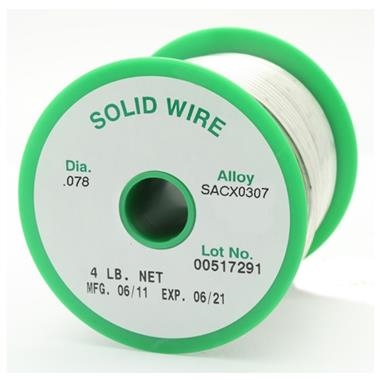

Alpha - SACX0307 Solid Wire Solder - .078" Dia., 4 Pound Spool - Priced per Pound (MOQ 4 lb)

-

Add to Cart

-

-

- $39.98

Quantity Pricing

- $39.98

- $39.18

- $38.40

-

ALPHA Vaculoy SACX0307 is a lead-free alloy suitable for use as a replacement for Sn63 alloy in the wave solder process. The SACX0300 variant is used to stabilize / reduce the copper content in the wave solder bath, this requirement will depend on process conditions. As with all Alpha Metals bar solder, Alpha’s proprietary Vaculoy™ alloying process is used to remove certain impurities, particularly oxides. The product is further enhanced with the addition of 2 minor elements to reduce dross formation and improve the joint cosmetics. Melting point of SACX 307 alloy: 217-228° C

Features:

- Yield – Comparable to SAC305, superior performance for bridging compared to Sn99.3/Cu0.7 based alloys.

- Wetting Speed – 0.75 seconds typical wetting speed compares to SAC305 at 0.65 sec and superior to Sn99.3/Cu0.7 based alloys at 1.0 sec.

- Dross Generation – lowest in class due to the Vaculoy process in conjunction with the addition of a dross reducing agent.

- Lowers Total Cost of Ownership due to the lower material cost, high yields and low dross generation.

- Gives very good solderability due to the fast wetting speed.

- Gives very good drainage and hence lower levels of bridges due to the formulation containing Silver.

- Delivers good performance across a range of flux technologies.